ABOUT US

Breakthrough

Kunshan BCTM

INTRODUCTION

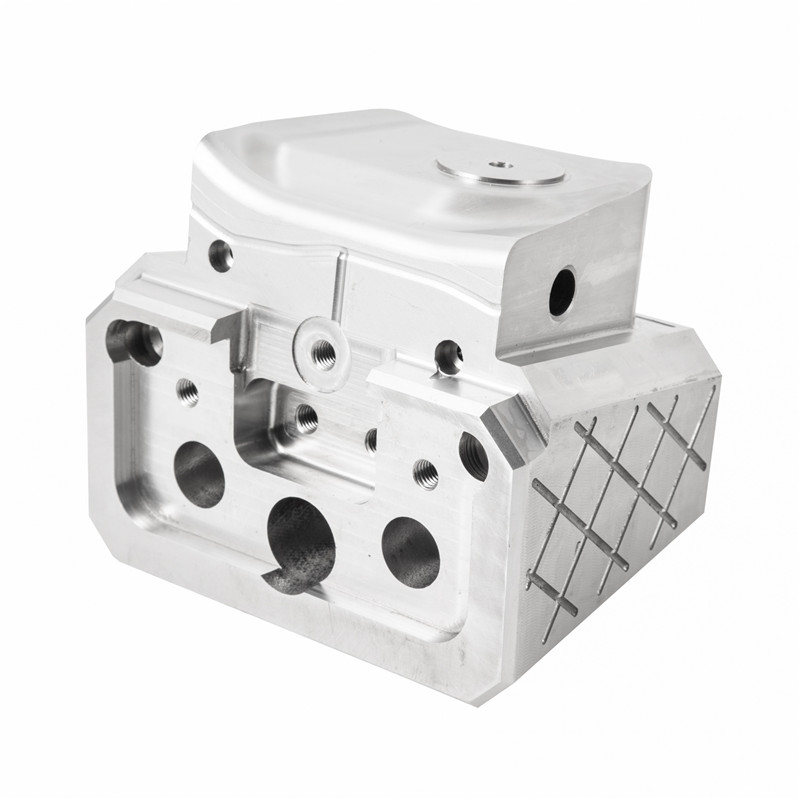

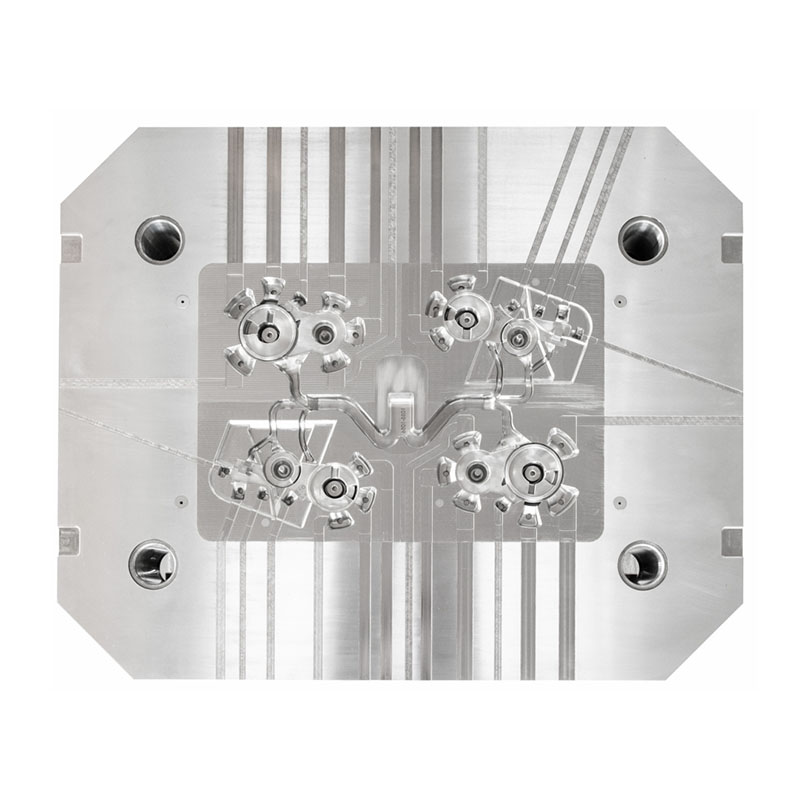

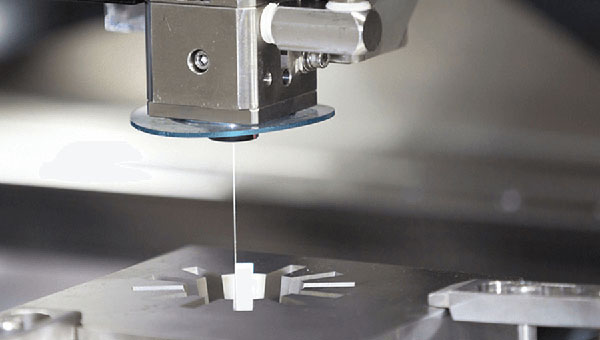

Kunshan BCTM Co., Ltd. Was founded in 2007 in Kunshan. We are an enterprise that professionally engaged in the design and processing of die casting mold, injection mold and related components. We have the ability to provide one-stop service for customers. Our products include die casting mold, injection mold, stamping mold, precision components and precision mold base. Our products serve the automobile, home appliances, electronics, packaging and other industries. Our products are used in automotive, applicances, lighting, home, medical, packaging and office furnishings, etc. Our team is professional, mature and experienced.

-

-Founded in 2007

-

-16 years experience

-

-+More than 5 products

-

-$More than 7 application fields

products

Innovation

NEWS

Service First

-

2023 Fakuma Exhibition from Oct.17-21

Shanghai Klak-Ling attended the Fakuma International Trade fair for Plastics Processing 2023 from Oct.17-21 in Friedrichshafen, German. It’s held two sessions in 3 years. The Organizer is P.E. SchallGmbH & Co. Fakuma International Trade fair for Plastics Processing ...

-

Unlocking the Benefits of High Precision Sliders in Industrial Manufacturing

High precision sliders are essential components of several industrial manufacturing processes, primarily in the production of electronic gadgets, automotive parts, and aerospace equipment. Manufacturers rely on these sophisticated machinery to ensure complete product quality and consistency while...